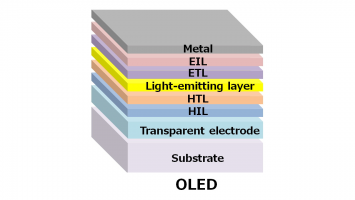

LED chips coming from serial production to have some minor differences, such as light color, light output, and working voltage. Gathering LEDs with similar characteristics in the same group is called binning.

The differences in light color are the most noticeable difference between the consumer. For example, when you pass through a tunnel or subway, some of the lightings on the ceiling can be seen yellow color and some lightings can be seen white.

Some of the white color LEDs can be different each other. Some can be seen bluish, some can be seen yellowish. When these LEDs light up separately, it is hard to see the difference. However, this difference can easily be distinguished when they come inside by side. For example, A LED you bought as 4500K can be in the range of 4250 K – 4750 K color temperature. When these LEDs are used in a fixture, differences can easily be seen at the point where the light comes out. Even the LEDs with the same color used in different fixtures, color differences can be seen easily when the fixtures come side by side. Binning, LEDs with the same groups, can be in a narrow range like 4400 K- 4500 K. In such a narrow range, the difference in color temperature may not be understood. In addition to white LEDs, color LEDs are also classified according to color coordinates. Color binning or CCT Binning is the process of categorizing LEDs by light color.

LED coming from serial production does not have the same light output or lumen value. A group of LEDs out of serial production has high light output, while the other group may have a lower value. In order to define these differences, a group can be created according to lumen values which are called Lumen Binning. The lumen classification is extremely important to calculate the light output of the lighting element.

The LEDs begin to emit light when the electric current passes through it under a certain voltage. However, this voltage value may vary between LEDs. Working voltage is an important parameter for selecting the LED drive. The need of a classification becomes a must according to this value which is called Forward Voltage Binning.

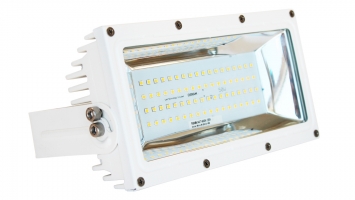

Grouping of LEDs is done by the manufacturer company. The color, Lumen, forward voltage bin tables are located in the LED’s data file. LED bins are very important for lighting manufacturers. These features have a direct effect on the performance of the LED fixture.

It should be noted that there is chromatic deviation when the LEDs are being used in time. Therefore, there may be significant color differences between a newly created fixture and a used fixture with LEDs in the same bin.

COMMENTS

MAKE A COMMENT