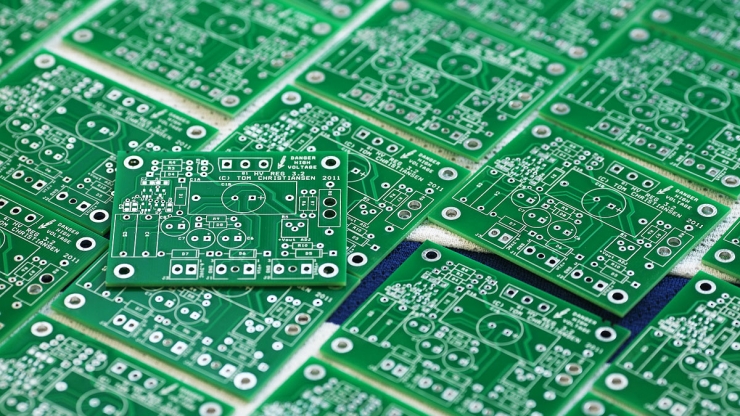

PCB is used to install electronic circuit equipment. There are conductive paths on it. PCB stands for Printed Circuit Board.

PCB support electronic components mechanically and provide necessary electrical connection to operate. PCB may have multiple layers for complex circuits.

PCB generally made of a copper board which is compressed between two layers.

Circuit components are installed to PCB by soldering. Circuit component is fixed to the PCB by soldering, therefore, connected electrically.

Green is accepted as standard color for PCB. However, it can be black, white, red, blue and yellow. The color of PCB has no effect on electrical performance of circuit.

There are one or more than one PCB inside of electronic devices such as mobile phone, radio, TV, camera, computer. PCBs are also used in solid-state lamps, light source of fixtures and drivers.

The base material is very important for PCB selection. Base material is affected by PCB performance and application scope. CEM-1 and FR-4 are commonly used for PCB’s

The mechanical performance of FR-4 is better than CEM-1. CEM-1 is more fragile but electrical specifications are very close to FR-4. CEM-1 is cheaper than FR-4. That is why CEM-1 is very popular in electronic industry.

In lighting sector, aluminum PCB’s are preferred because of their thermal performances. Aluminum PCB offers perfect thermal conductivity for circuit components that need cooling.

In addition to the lighting sector, aluminum PCBs are used in telecommunication, automotive, computer and medical industries.

Aluminum PCB basically made up of three layers. There is a non-conductor layer on aluminum base board. Non-conductive layer transfers the heat to aluminum layer when it provides electrical resistivity. On the non-conductive layer, there is a conductive copper layer.

COMMENTS

MAKE A COMMENT